Mist Smoke Collector BL-VF_A

產品說明

CNC Mist & Smoke Filtration Collector

Where do MIST AND SMOKE come from??

Metalworking Mist and Smoke – In machining processes, the coolant and lubricant liquids are applied, the generated force and heat create mist and smoke. The type of contaminant depends on what coolants are being used and the machining parameters. Water-soluble coolants produce a mist with larger droplet sizes where straight oils produce more of a smoke that can be submicron in size. Higher speed machines or processes that generate a large amount of heat will produce higher concentrations of contaminants.

Why do we need to collect MIST AND SMOKE??

Key benefits gained from using from CNC dust and mist collectors include:

Health Protecting for worker

Reduced exhaust air make-up requirements up to 80% through recirculated conditioned air

Extended machine life-time

Recycle lubricants to reduced operational costs

Improved and keep product quality

Reduced housekeeping costs

Compliance with even the strictest federal, state and local environmental standard/ regulation

Health Protecting for worker

Reduced exhaust air make-up requirements up to 80% through recirculated conditioned air

Extended machine life-time

Recycle lubricants to reduced operational costs

Improved and keep product quality

Reduced housekeeping costs

Compliance with even the strictest federal, state and local environmental standard/ regulation

BL-001-VF_A

Product Description

With advanced internal filter (BL-001-VF_A), BL-VF Collector can filters & collect water-soluble coolant, straight oil, and the most challenging, oily smoke (water, smoke, oil). It is an extreme powerful three types of mist (water, smoke, oil) collector to fit a variety of machining operations, environment, and other industrial process requirements

Product Specification

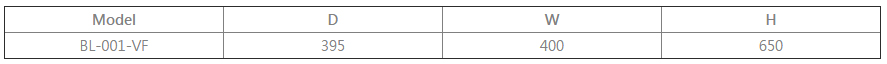

Dimensions (mm)

Accessories

1. Duct flange

2. Oil return tube connector

3. Duct (3 meters)

4. Oil return tube

5 meters

2. Oil return tube connector

3. Duct (3 meters)

4. Oil return tube

5 meters